Hydraulic

Gear Pumps

What You Get

Tupelo Hydraulics has over 40 years combined experience, we have the ability to help you with all your hydraulic gear pump needs.

- Excellent Customer Service

- Fast Turn Around Time

- Warranty Coverage

specializing in hydraulic gear pump repair

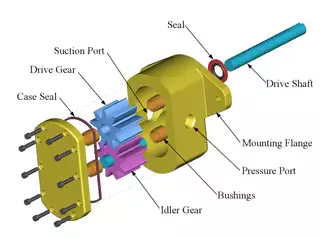

As the gears rotate they separate on the intake side of the pump, creating a void and suction which is filled by fluid. The fluid is carried by the gears to the discharge side of the pump, where the meshing of the gears displaces the fluid. The mechanical clearances are small— in the order of 10 μm. The tight clearances, along with the speed of rotation, effectively prevent the fluid from leaking backwards. The rigid design of the gears and houses allow for very high pressures and the ability to pump highly viscous fluids. Tupelo Hydraulics can repair your hydraulic gear pump.

Hydraulic Gear Pump Exploded View

External Hydraulic Gear Pump

Internal Hydraulic Gear Pump

Hydraulic Gear Pump/Repair

Tupelo Hydraulics offer the following Hydraulic Pumps and Hydraulic Pump Repair and Product Lines

See our list by clicking below

American-March Pumps

Products: Helical gear pump

Applications: Blending, mixing, transfer, solvents, oils, chemicals, Heavy, Viscous Liquids

Viking Pump

Products: Internal and External Gear Pumps (Mag Drive, Heavy Duty Alloy, Abrasive Liquid, Hygienic)

Applications: Industrial applications from chemicals, fuels and plastics, to materials that are thin, thick, hot, cold, liquid, solid, and much more.

KSB

Products: Helical gear pump, self‐priming

Applications: Fuel feed, handling fuel, lubricating oil and viscous fluids, lubrication systems

Gorman-Rupp Pumps

Products: Rotary gear pumps: medium and heavy duty, abrasive handling pumps. Compact and standard size rotary gear pumps

Applications: Handling viscous liquids, abrasive liquids

Parker

Products: Hydraulic Gear Pumps

Applications: Material Handling, Turf Care, Agricultural, Construction Equipment

BSM Pump Corporation

Products: Rotary Gear Pumps, Automatic Reversing Gear Pumps

Applications: Pressure lubrication, hydraulic service, fuel supply, and general liquid transfer, recirculating, mixing, and transfer applications

Suntec

Products: Gear Pumps for fuel

Applications: Light oil, B10 heating oil/biofuel blend (as defined in DIN V51603-6) and kerosene. One or two-pipe system. System with in-line solenoid valve to assure cut-off function.

HYPRO

Products: Hydraulic-Driven Gear Pump

Applications: Agriculture & Turf Spraying, Transfer & Mixing

Rexroth Bosch Group

Products: External Gear Pumps, Internal Gear Pumps

Applications: Hydraulic fluid transport to the pressure range

Corrosion Fluid Products Corp

Products: Double Helical Rotary Gear Pumps

Applications: General Purpose, Chemical Processing, Greases and Fats, Petroleum Production and Refining, Syrups, Utility, High Viscosity Polymers, Marine, Pulp and Paper

Roper Pump Company

Products: Gear Pumps: High Pressure External Gear Pump, Magnetic Drive, Seal-Less Helical Gear Pump

Applications: General transfer applications, Pressure lubrication, Hydraulic lift, Mixing, Blending and Recirculating a variety of fluids, Pumping Viscous Liquids, Crude Oil, Condensate, Well treatment chemicals, Produced water, Waste oil

Delta Industries Inc

Products: Rotary Gear Pumps, ANSI Process, Centrifugal Pumps, High Pressure, Progressive Cavity, Sanitary 3A, Hygienic, Metering, Vertical turbine, Submersible, Air Operated Diaphragm, Non Clogging, Food Transfer, Screw, Slurry, Rubber lined, Cleaning, Split Case Pumps

Brands: Sulzer, Moyno, WEIR, Roto-Jet, WEMCO, Ampco, Floway, Versamatic, Tsurumi, ABS

NNT Corporation LLC

Products: Rotary Gear Pumps, Automatic Reversing Gear Pumps

Applications: Pressure lubrication, hydraulic service, fuel supply, and general liquid transfer, recirculating, mixing, and transfer applications

Apex Pumping Equipment

Products: Helical Gear Pumps

Applications: Oil field service, Brine and raw water, Sludges and slurry, Waste oils, tallow, etc., Sealant coats, Molasses feeds, Fertilizers, Paper pulps

GROCO

Products: Positive Displacement Gear Pums for marine applications

Applications: Deck-wash, fuel transfer, ballast transfer, and oil change

ZEELINE (National-Spencer, Inc.)

Products: 12 Volt and 115 Volt Electric Gear Pumps

Applications: For transferring gasoline, kerosene, diesel fuel, mineral spirits heptane, stoddard solvents

PSG

Products: Gear Pumps

Applications: Adhesive, Biofuel, Chemical, Food Process, Lube Oil and Grease, Paint and Coating, Petrochemical, Petroleum Additives

Polyurethane, Printing, Resin, Soap

Coker Pump & Equipment Company

Products: Gear Pumps

Applications: Asphalt, Chemical, Corn Syrup, Fuel Oil, Florinert, Heat Transfer Fluids, Molasses, Polymer & Resins

- Parker Hannifin

- Advanced Fluid Systems, Inc.

- Advanced Hydraulics, Inc.

- AeroControlex

- Albany Pump Company Ltd.

- All World Machinery Supply Inc.

- American Eagle Accessories Group

- American Lab & Systems

- AZ Hydraulic Engineering, Inc.

- Barbee Engineered Testing Systems

- BJM Pumps, LLC

- Bosch Rexroth Corporation

- Viking Pump, Inc.

- KSB Inc

- Gorman-Rupp Pumps

- Parker Hannifin Corp (GEAR PUMP DIVISION)

- BSM Pump Corporation

- SUNTEC Industries

- HYPRO (Pentair Ltd.)

- Gorman-Rupp Industries

- Corrosion Fluid Products Corp

- Roper Pump Company

- Delta Industries Inc

- NNT Corporation LLC

- Apex Pumping Equipment

- GROCO

- ZEELINE (National-Spencer, Inc.)

- PSG

- Coker Pump & Equipment Company

- Abex Denison Hydraulics

- Atchley Hydraulics

- Bosch Rexroth Hydraulics

- Caterepillar Hydraulics

- Cessna Hydraulics

- Charlynn Hydraulics

- Commercial Intertech Hydraulics

- Commercial Scheering Hydraulics

- Commercial-Parker Hydraulics

- Continental Hydraulics

- Continental Pumps

- Daikin Hydraulics

- Danfoss Hydraulics

- Denison Hydraulics

- Denison-Parker Hydraulics

- Dynett Hydraulics

- Dynapower Hydraulics

- Eaton Hydraulics

- GearTek Hydraulics

- Hitachi Hydraulics

- Hydreco Hydraulics

- John Deere Hydraulics

- Kawasaki Hydraulics

- Kawasaki Staffa Hydraulic Motors

- Kayaba Hydraulics

- Kobelco Hydraulics

- Komatsu hydraulics

- Linde Hydraulics

- LinkBelt Hydraulics

- Mitsubishi Hydraulics

- Moog Hydraulics

- Oilgear Hydraulics

- Parker Hydraulics

- Parker-Servo Valves

- Racine Hydraulics

- Rexroth Hydraulics

- Samsung Hydraulics

- Sauer Danfoss Hydraulics

- Sauer Sundstrand Hydraulics

- Sunfab Hydraulics

- Uchida Hydraulics

- Vickers Hydraulics

- Volvo Hydraulics

- White Hydraulics

Hydraulic Gear Pump Applications

Learn more by clicking below

- Barber-Greene Pavers Sundstrand Hydraulic Gear Pump Repair

- Blaw-Knox Pavers Dynex-Rivett Gear Pump Repair

- Bomag Rollers Linde, Rexroth, Poclain Gear Pump Repair

- Case Backhoe Webster, Commercial Gear Pump Repair

- Case Track Loaders Sundstrand Gear Pump Repair

- Case Dozer Sundstrand Gear Pump Repair

- Case Wheel Loader Commercial Gear Pump Repair

- Case Excavator Linde, Kawasaki Gear Pump Repair

- Case Skid Loaders Sundstrand Gear Pump Repair

- Caterpillar Dozer Linde, Rexroth, Tyrone, Vickers Gear Pump Repair

- Caterpillar Track Loaders Cat, Linde, Vickers, Tyrone Gear Pump Repair

- Caterpillar Excavators Linde, Rexroth, Kawasaki, Cat Gear Pump Repair

- Caterpillar Milling Machine Sundstrand, Ross Gear Pump Repair

- Caterpillar Motor Graders Vickers Gear Pump Repair

- Caterpillar Scrapers Tyrone, Vickers Gear Pump Repair

- Caterpillar Backhoe Rexroth, Vickers Gear Pump Repair

- Caterpillar Wheel Loaders Vickers, Tyrone, Linde Gear Pump Repair

- Daewoo Excavator Linde, Kawasaki Gear Pump Repair

- John Deere Backhoe Deer, Oil Gear (Hydura) Gear Pump Repair

- John Deere Dozer Sundstrand Gear Pump Repair

- John Deere Track Loader Sundstrand Gear Pump Repair

- John Deere Wheel Loader Sundstrand, Tyrone, Rexroth Gear Pump Repair

- John Deere Excavator Linde, Uchida, Hitachi, Kawasaki Gear Pump Repair

- Dresser Track Loader Linde Gear Pump Repair

- Gradall Excavator Commercial, Rexroth, KYB Gear Pump Repair

- Grove Excavator Commercial Gear Pump Repair

- Hamm Rollers Linde Gear Pump Repair

- Hitachi Excavator Hitachi, Kawasaki Gear Pump Repair

- Hyundai Excavator Kawasaki Gear Pump Repair

- Ingersoll-Rand Roller Sundstrand, Poclain Gear Pump Repair

- Kato Excavator Kawasaki Gear Pump Repair

- Kobelco Excavator Kawasaki Gear Pump Repair

- Komatsu Dozer tyrone, Commercial, Hydreco Gear Pump Repair

- Komatsu Rollers Vickers, Sundstrand Gear Pump Repair

- Komatsu Wheel Loaders Komatsu Gear Pump Repair

- Komatsu Excavators Komatsu Gear Pump Repair

- Liebherr Excavators Linde, Liebherr Gear Pump Repair

- Liebherr Excavators Track Loader Linde Gear Pump Repair

- Liebherr Track Loader Linde Gear Pump Repair

- Linkbelt Excavator Linde, Uchida Gear Pump Repair

- P&H Crane Rexroth, Tyrone, Commercial Gear Pump Repair

- Putzmiester Concrete Pumps Rexroth Gear Pump Repair

- Schwing Concrete Pumps Rexroth Gear Pump Repair

- Volvo Wheel Loaders Tyrone, Vickers Gear Pump Repair

- Volvo Read Dump Commercial Gear Pump Repair

- Wirtgen Milling Machine Rexroth Gear Pump Repair

Call Tupelo Hydraulics for all your pump repair needs.

How does a Hydraulic gear pump work